How do air filters perform under real conditions? Do filters perform as well as their literature claims? How do filters differ from each other, in terms of pressure drop at time of installation vs. weeks later, structural integrity, dust-loading uniformity and other factors? The mobile filter testing lab has proved to be an invaluable tool for testing various filters simultaneously under identical ambient conditions, (RH%, temp, air flow, etc). for extended periods of time.

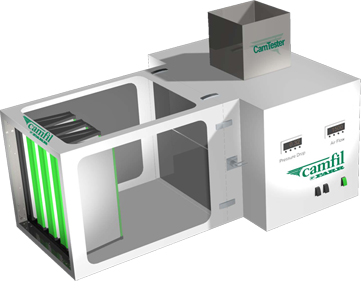

The mobile filter testing lab has four separate ducts, each of which has a pre-and fine filter section, and a separately controlled fan. Measured values from all filter steps, orifices, temperature and relative humidity are logged continuously. Logged values can be retrieved on site, or via wireless modem.

The mobile filter testing lab can be sited anywhere there’s an electrical connection. Four combinations of filters can be tested at the same time. The mobile filter testing lab can provide article, stub and gas measurements. It is an excellent tool for generating objective and scientifically valid data regarding one of the most important recurring purchases companies make.

Case in Point

One of the nation’s largest independently-owned food retailers, with more than 300 stories, changed their existing filters based on pressure drop every two months. Several of the stores were persuaded to convert to the 30/30 air filter, and as a direct result,extended filter life to four months.

This caught the attention of management, which summoned the mobile filter testing lab to its San Antonio, Texas corporate office for evaluation. In an unusual double-blind study, the 30/30s were tested against two competitors.

After two months, the 30/30 demonstrated a 50% advantage on pressure drop compared to one competitor. The second competitor’s filter was disqualified when it suffered particle breakthrough and structural collapse.