How can you be sure that you have selected the best air filter for your application? Industry test reports and material in manufacturers’ literature or packaging may be a good start, but will they provide a true indication of a filter’s value over its entire service life, in your system? After all, that’s what matters. (In […]

Category Archives: TOOLS / SAVINGS

We guarantee that Camfil 5-Star Premium Filters will substantially reduce HVAC-related energy consumption, require less frequent change-outs, and reduce waste and environmental impact. We’re the only air filtration company that guarantees our product performance. Look for the Camfil guarantee logo and 5-Star rating.

The Mobile Media Tester takes particle count and efficiency measurements in order to analyze and compare fine fiber vs. coarse charged fiber bag filter products. Coarse fiber (synthetic) media is cheaper than fine fiber (microfiber glass) media. In some cases the cost differential may be as high as 20%, sometimes passed on in more competitive […]

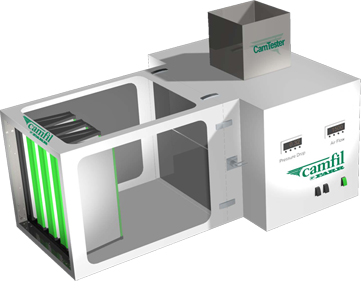

CamTester is an advanced field testing device. Actual pressure drop and airflow for various filter products can be compared for real-life verification of performance. Many customers use CamTester to compare with lab testing data and vendor literature claims. We welcome these comparisons!

How can filter users differentiate manufacturers’ claims and make intelligent decisions as to what products best meet their needs? In the past, test reports were one answer. But today’s test lab methodologies may not offer a true barometer of a filter’s performance over time. The reason: these filters are not tested under the real world […]

SAVER simplifies the collection of site survey data. This specially-configured PDA was engineered to work with Life Cycle Costing Software, which calculates the precise Life Cycle Cost for a specific filter, (ours or a competitor’s) in any given AHU. The LCC program adjusts to accommodate real-world outdoor air characteristics, hours of operation and fan efficiency, […]

How do air filters perform under real conditions? Do filters perform as well as their literature claims? How do filters differ from each other, in terms of pressure drop at time of installation vs. weeks later, structural integrity, dust-loading uniformity and other factors? The mobile filter testing lab has proved to be an invaluable tool for […]

An air filter life cycle cost analysis shows a user how to obtain the best value. Although air filters are viewed by some as a commodity-type replacement item similar to rest room paper products or basic cleaning materials their application in HVAC systems makes them much more. Choosing the wrong filter can cost a facility […]